Raw Material:PPGI,PPGL

Material Thickness:24/26 Gauge (0.4-0.6 Mm)

Machine Frame:350mm H beam structure

Product Features

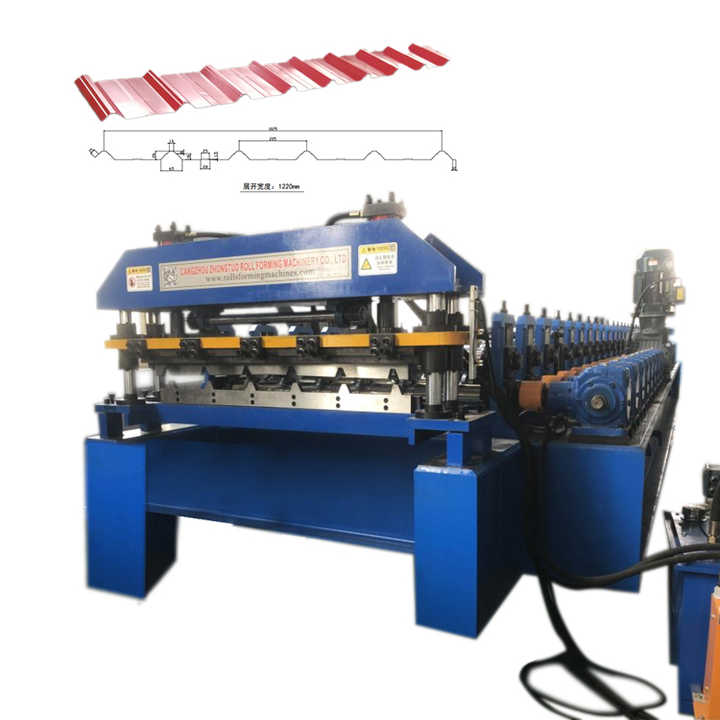

High Speed Trapezoidal Roof Sheet Roll Forming Machine

High-speed trapezoidal roof sheet roll forming machine is an essential piece of equipment for businesses involved in the production and installation of roofing materials. Its ability to efficiently produce high-quality trapezoidal

profiles makes it a valuable tool for meeting the demands of the construction industry.

Design Idea:

Fast Speed: 25m/min forming speed ,very fast ,more efficiency.

Stable Forming:the roller stand is vertical cast steel stand ,gearbox driving,very strong ,the forming very stable and final product very accurate.

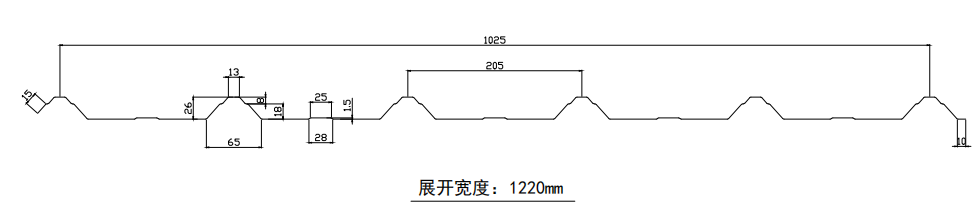

Profile drawing for reference:

Roofing sheet produced by trapezoidal roofing sheet machine has many different shapes,usually different countries have its own popular design ,we can customize the machine as customers’ demand.

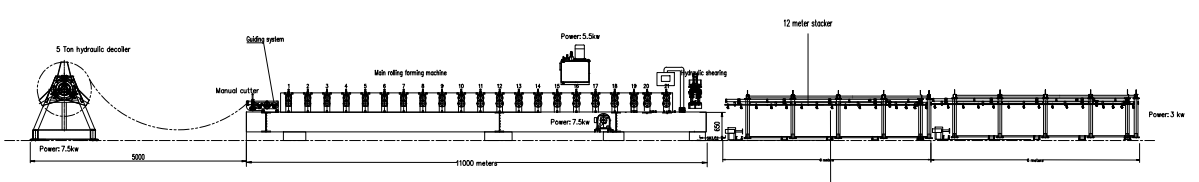

Processing Flow

Uncoiling → Feeding Material Into Machine →Roll Forming → Auto Cutting →Products Receiving Table

Capacity:5 tons

Coil inner diameter:450-550mm

Feeding width: max 1220mm

Function:Supporting the coils and doing uncoiling,It adopts the hydraulic cylinder to make the decoiler expand and fit to the inner diameter of coils. It is equipped with the cantilever.Motor drive the coils running and can do forward and reverse running as well as do the decoiling with tension.

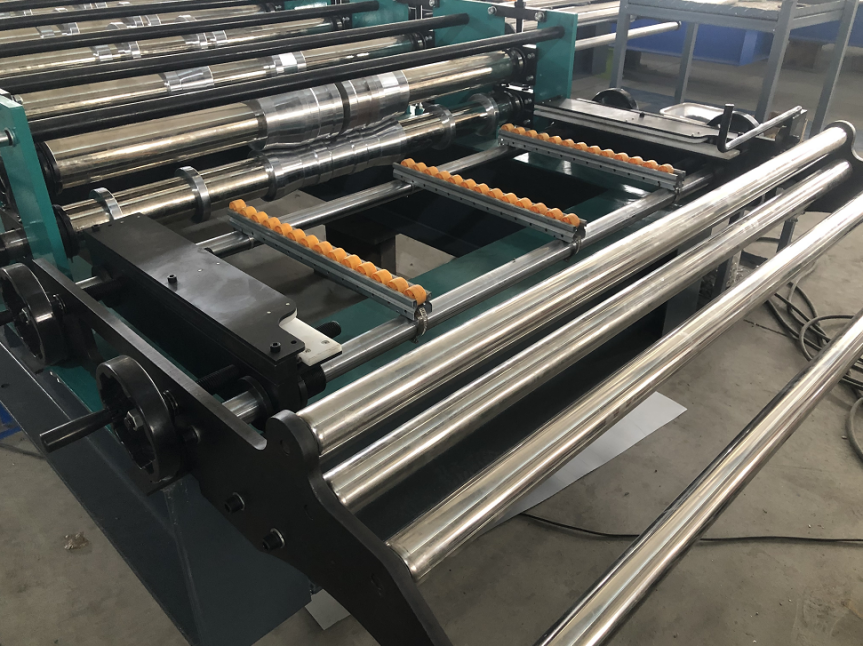

Feeding Device

1.Hand wheels on both sides can be used to adjust the feeding width.

2.Four stainless rollers can make the material go into the trapezoidal roof sheet making machine smoothly and prevent the scratch on the material surface.

3.There are three rows of orange plastic rollers can make the steel coil go into the machine smoothly.

Roll Forming And Transmission Device

1.rollers thick chromed good hardness for long service time.

2. Each roller has number and with keynotes, it can fix on the shaft stablely

3.gear and double chain,stable

Hydraulic Cutting Device

We use four pillars cutting system structure, it can make sure the cutting stable

PLC control system

PLC brand:Delta

● Encoder brand:Omron

● Electrical components:Schneider

●Operating language:English and Chinese(or as requested)

You can set the orders on this part,changing product length and quantity,it is really easy to operate,and there are aviation plugs to make it much easier to install the machine while it arrived.

Hydraulic station

● Hydraulic station motor:7.5KW

● Hydraulic oil:46# hydraulic oil

● Main components:Include a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. And one of electromagnetism valve

Automatic Stacker

Function :Collect the finished product automatically ,save labor,and very efficiency.

Updated on January 26, 2024

PARAMETER

Raw Material:PPGI,PPGL

Material Thickness:24/26 Gauge (0.4-0.6 Mm)

Machine Frame:350mm H beam structure

Material Of Rollers:High grade 45# forged steel,Chromed treatment

Roller Stand:Vertical cast steel structure

Forming Stations:16 rows

Diameter Of Shafts:Φ80mm Solid

Material Of Shafts:High Grade 45#,With Heat Treatment

Forming Speed:25 M/Min

Voltage:380v/50hz/3p (As Requested)

Transmission Way:By gearbox

Main Motor:11 KW

Cutting Blade Material:Gcr12 quenched treatment

Cutting Type:hydraulic post cutting

Driving method:By pillar type Cylinder

VIDEO

PICTURE

FAQ

1. How to visit your company?

1.Fly to Beijing airport, By high speed train From Beijing Nan to Cangzhou Xi (1 hour).

2.Fly to Tianjin airport, By high speed train From Tianjin to Cangzhou Xi (0.5 hour).

3.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

2. Can you be responsible for transport?

Yes, please tell me the destination port or address. we have rich experience in transporting.

3. What will you do if the machine is broken?

We provide 1 year free warranty and free technical support for the whole life of any machine. If the broken parts can't repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the roll forming machine.

4. Do you sell only standard machines?

No, most of our machines are customized according to customers specifications, also adopt top brand components.

5. Do you have after-sales support?

Yes, we are happy to provide advice and we also have skilled technicians available across the world.

6. What's your payment terms and delivery time?

30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before delivery. Of course your payment terms are acceptable. After we get down payment, we will arrange production. About 45 workdays for delivery.

7. How can we be assured that you will deliver us quality machine with spare parts ?

1. Customers can come to our factory, or send the technical people to our factory for checking the quality.

2. We can send the technicians to the buyer's factory for the installation of the machine.8. Can you manufacture the roll forming machine according to my profile drawing or picture of finished product ?

Yes. Our rich experienced technical team can draft the accurate profile drawing, provide the most suitable technical solution for your required roll forming machine.

Geno Technology Development Hebei Co., Ltd

Mob.: 8613091162987

E-mail: web@geitgroup.com

WhatsApp: 8613091162987

Add.: N0.4 Road, Economic Develop Zone, Botou County, Cangzhou, Hebei, China

Geno Technology Development Hebei Co., Ltd All Rights Reserved | Sitemap