Raw Material:PPGI,GI

Material Thickness: 0.3-0.8 Mm

Product Features

High Speed Metal Corrugated Roof Tile Making Machine

High-speed metal corrugated roof tile making machinery refers to a specialized type of equipment used in the construction industry to manufacture corrugated metal roofing materials.

These machines are designed to produce high-quality roof tiles quickly and efficiently, meeting the demands of modern construction projects. The technology involved in these machines

allows for precise control over the production process, resulting in roof tiles that are durable, cost-effective, and environmentally friendly.

Design Idea:

High speed:0-40m/min(speed customized 0-80m/min)

Special Design Cutting Device:Whole producing line just need one person for operation.

Stable Transmission: gearbox drive.

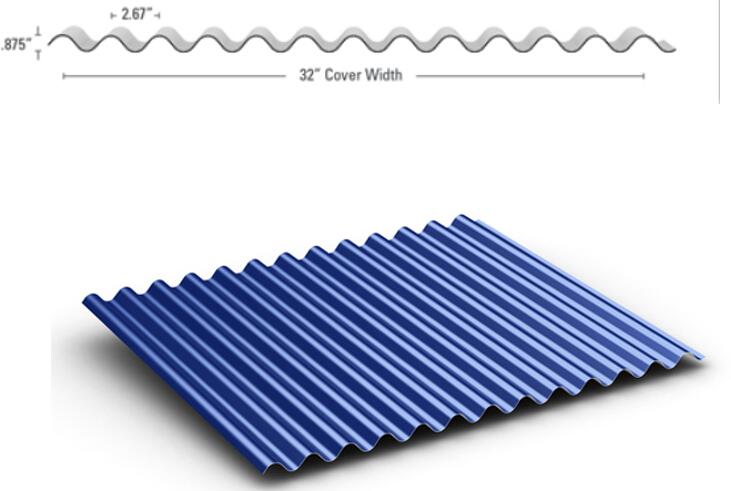

Profile drawing for reference:

this type corrugated roof sheet very hot sale in US.As we sold many machines to America,we have rich experience on it to confirm the finished product good and suit for market.

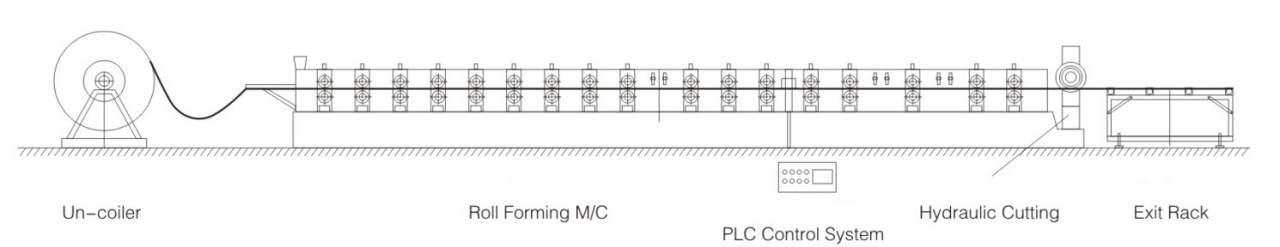

Processing Flow of roll forming machine:

Decoiler-feeding material-roll forming-cutting-product receiving table

Feeding device

1. Rubber rollers protect raw material surface

2. With handwheels easy adjust for feeding different thickness raw material.

3.the platform width is adjustable by hand wheel, have the bearing inside to protect the edge of the steel sheet.

Roll Forming Device

1.45# Steel,Chromed Treatment (Cr Thickness:0.05 Mm), Anti-Corrosion,Increase Hardness, thick chromed good hardness for long service time.

2. Each roller has number and with keynotes, it can fix on the shaft stablely

Transmission device

Gearbox transmission,stable and no loose.

Hydraulic Cutting Device

1.Work type:hydraulic servo track cutting servo motor 5.5KW

2.Driving method:By pillar type Cylinder

3.Hydraulic motor power:4 kw

4.Cutter material :GB-Cr12 with heat treatment

5.Cutting length tolerance ±10m/2mm

PLC control system

PLC brand : Delta

Inverter brand: Delta

Low electric part: Schneider

Encoder: Omron

Function:

1.Adopted aviation plugs,easy installation.

2.Full automatic easy operation.

3.Operation language:English(provide customized)

4.National coinsurance,spar parts Brand Siemens and Schneider.

Hydraulic station

7.5kw motor with cooling system for long time using.

3m Conveyor

6m Automatic Stacker

Updated on January 25, 2024

PARAMETER

Raw Material:PPGI,GI

Material Thickness: 0.3-0.8 Mm

Machine Frame:350# H Steel Frame Welded

Machine Structure:Vertical Arch Frame Structure

Material Of Rollers:45# Steel,Chromed Treatment (Cr Thickness:0.05 Mm), Anti-Corrosion,Increase Hardness, Ensure The Precision And Good Abrasion Performance.

Forming stations:21 stations

Diameter of shafts:Φ80mm

Material of shafts:45# Steel Tampering Treatment, Prevent Deformed And Improve The Hardness

Forming speed:About 0-40m/min

Voltage:380v 50hz 3phase Or As Request

Transmission:1.Gear Box Transmission

2. Material of Gear: 20 Crmnti

3.Material Of Gear Box: Iron Casting

4.The connection between gear boxes are chains

5.Gear box will connect with the rolling station one for one

6.Advantage: can improve the speed directly after cutting

Work power:11 kw ( gear reducer and servo motor driving)

Cutting blade material:Cr12Mov quenched treatment to improve hardness

Cutting type:No stopping Hydraulic cutting

Machine weight:about 15 Tons

Machine dimension:about 10000*2000*1400 mm

VIDEO

PICTURE

FAQ

1. How to visit your company?

1.Fly to Beijing airport, By high speed train From Beijing Nan to Cangzhou Xi (1 hour).

2.Fly to Tianjin airport, By high speed train From Tianjin to Cangzhou Xi (0.5 hour).

3.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

2. Can you be responsible for transport?

Yes, please tell me the destination port or address. we have rich experience in transporting.

3. What will you do if the machine is broken?

We provide 1 year free warranty and free technical support for the whole life of any machine. If the broken parts can't repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the roll forming machine.

4. Do you sell only standard machines?

No, most of our machines are customized according to customers specifications, also adopt top brand components.

5. Do you have after-sales support?

Yes, we are happy to provide advice and we also have skilled technicians available across the world.

6. What's your payment terms and delivery time?

30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before delivery. Of course your payment terms are acceptable. After we get down payment, we will arrange production. About 45 workdays for delivery.

7. How can we be assured that you will deliver us quality machine with spare parts ?

1. Customers can come to our factory, or send the technical people to our factory for checking the quality.

2. We can send the technicians to the buyer's factory for the installation of the machine.8. Can you manufacture the roll forming machine according to my profile drawing or picture of finished product ?

Yes. Our rich experienced technical team can draft the accurate profile drawing, provide the most suitable technical solution for your required roll forming machine.

Geno Technology Development Hebei Co., Ltd

Mob.: 8613091162987

E-mail: web@geitgroup.com

WhatsApp: 8613091162987

Add.: N0.4 Road, Economic Develop Zone, Botou County, Cangzhou, Hebei, China

Geno Technology Development Hebei Co., Ltd All Rights Reserved | Sitemap