Suitable material:Color steel sheet , galvanized steel sheet,aluminum sheet

Main motor power:3KW with Cycloidal reducer

Product Features

Galvanized Thin Material Barrel Corrugated Forming Machine

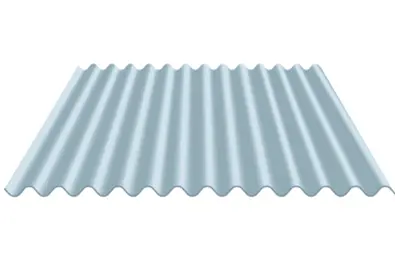

Galvanized thin material barrel corrugated forming machine is for making the corrugated roofing sheet,specifically for making the material thinkness lower than 0.4mm,and high-strengthen material.Different with the vertical type roofing sheet roll forming machine,this machine mainly for thin and high-strengthen material.And this type machine produced corrugated roofing sheet can have a change range.about the wave hight and distance.

The pictures for the finished product:

1. Why some sheet panel need the round wave machine while some sheet panel machine need the cold roll forming machine?

The difference is that, the sheet panel made by the round waveroofing sheet machine is much thinner and with hardness up to 550 Mpa.The thickness range is: 0.2-0.6.

But the thickness of the cold roll forming machine coil is 0.3-1.0mm as usual.

2. Which machine with higher capacity between the round wave machine and cold roll forming machine?

The capacity of the round wave machine and cold roll forming machine is more or less similar capacity, the barrel corrugated roofing sheet machine can press several pieces of the sheet at one time.

Updated on January 26, 2024

PARAMETER

Suitable material:Color steel sheet , galvanized steel sheet,aluminum sheet

Main motor power:3KW with Cycloidal reducer

Hydraulic station power:3KW

Hydraulic oil pump:CB-E 310

Thickness of material:0.15mm~0.5mm

Diameter of principal axis:70-90mm

Material expand width:1000,1200,1250mm

Electric tension:380V 3phase 50HZ or as the customer's requirements

Material of roller:High grade 45# forged steel plated with hard chrome plating

Controlling system:PLC

Processing speed:3-6m/min

Processing precision within:1.00mm (depend on design)

Material of cutting blade:Cr12 mould steel with quenched treatment

Kind of drive:0.6 inch chain link bearing model 6210

Roller station:8-20 Rollers

Roller material:High grade 45#steel; Cr12 quenching

Leak frame load-bearing:4.6T

VIDEO

PICTURE

FAQ

1. How to visit your company?

1.Fly to Beijing airport, By high speed train From Beijing Nan to Cangzhou Xi (1 hour).

2.Fly to Tianjin airport, By high speed train From Tianjin to Cangzhou Xi (0.5 hour).

3.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

2. Can you be responsible for transport?

Yes, please tell me the destination port or address. we have rich experience in transporting.

3. What will you do if the machine is broken?

We provide 1 year free warranty and free technical support for the whole life of any machine. If the broken parts can't repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the roll forming machine.

4. Do you sell only standard machines?

No, most of our machines are customized according to customers specifications, also adopt top brand components.

5. Do you have after-sales support?

Yes, we are happy to provide advice and we also have skilled technicians available across the world.

6. What's your payment terms and delivery time?

30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before delivery. Of course your payment terms are acceptable. After we get down payment, we will arrange production. About 45 workdays for delivery.

7. How can we be assured that you will deliver us quality machine with spare parts ?

1. Customers can come to our factory, or send the technical people to our factory for checking the quality.

2. We can send the technicians to the buyer's factory for the installation of the machine.8. Can you manufacture the roll forming machine according to my profile drawing or picture of finished product ?

Yes. Our rich experienced technical team can draft the accurate profile drawing, provide the most suitable technical solution for your required roll forming machine.

Geno Technology Development Hebei Co., Ltd

Mob.: 8613091162987

E-mail: web@geitgroup.com

WhatsApp: 8613091162987

Add.: N0.4 Road, Economic Develop Zone, Botou County, Cangzhou, Hebei, China

Geno Technology Development Hebei Co., Ltd All Rights Reserved | Sitemap